Precision SMT Manufacturing for High-Performance LED Lighting

In commercial, industrial, and outdoor lighting, reliability starts with precision manufacturing. At Epower, our SMT workshop ensures every LED lamp bead undergoes a meticulous process, from solder paste application to component placement and reflow soldering. These steps are critical for producing high-quality emergency lighting built to last.

Solder Paste: Controlled for Consistency

We implement a First-In-First-Out (FIFO) system and real-time temperature monitoring to maintain optimal solder paste quality. Applied in a fully automated dust-free environment, our process ensures uniform deposition, preventing defects like insufficient solder or bridging.

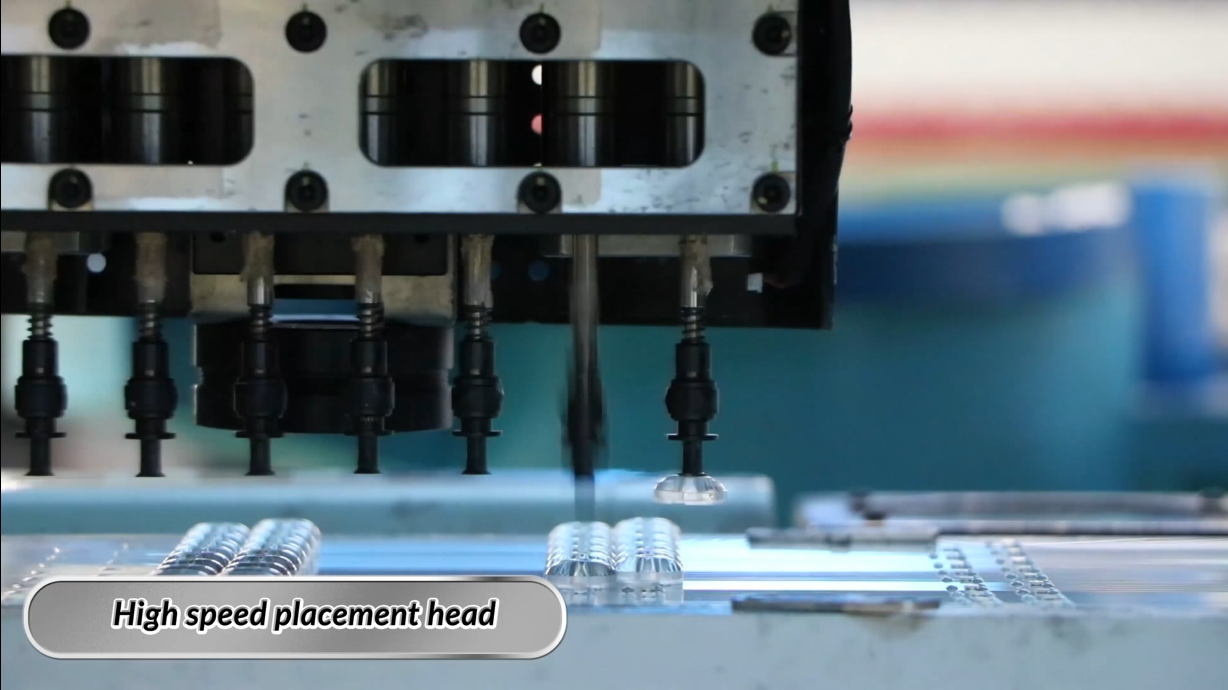

SMT Placement: Micron-Level Accuracy

Using high-speed pick-and-place machines, LED components are positioned with sub-micron precision. Vision alignment technology corrects placement in real-time, ensuring stability and performance in emergency exit signs, industrial lighting, and outdoor LED solutions.

Reflow Soldering: Reliable, Durable Bonds

Our multi-zone reflow ovens maintain precise temperature control, preventing cold joints and overheating. The result is strong, conductive solder joints, ensuring long-term reliability in emergency and high-performance LED lighting.

At Epower, we combine efficiency, precision, and automation to deliver top-tier LED solutions. Stay tuned as we explore inspection and testing, the final steps in guaranteeing quality.