Surface Finish in Injection Molding

The VDI (Verein Deutscher Ingenieure) is a German engineering association that has established standards for surface roughness in injection molding.

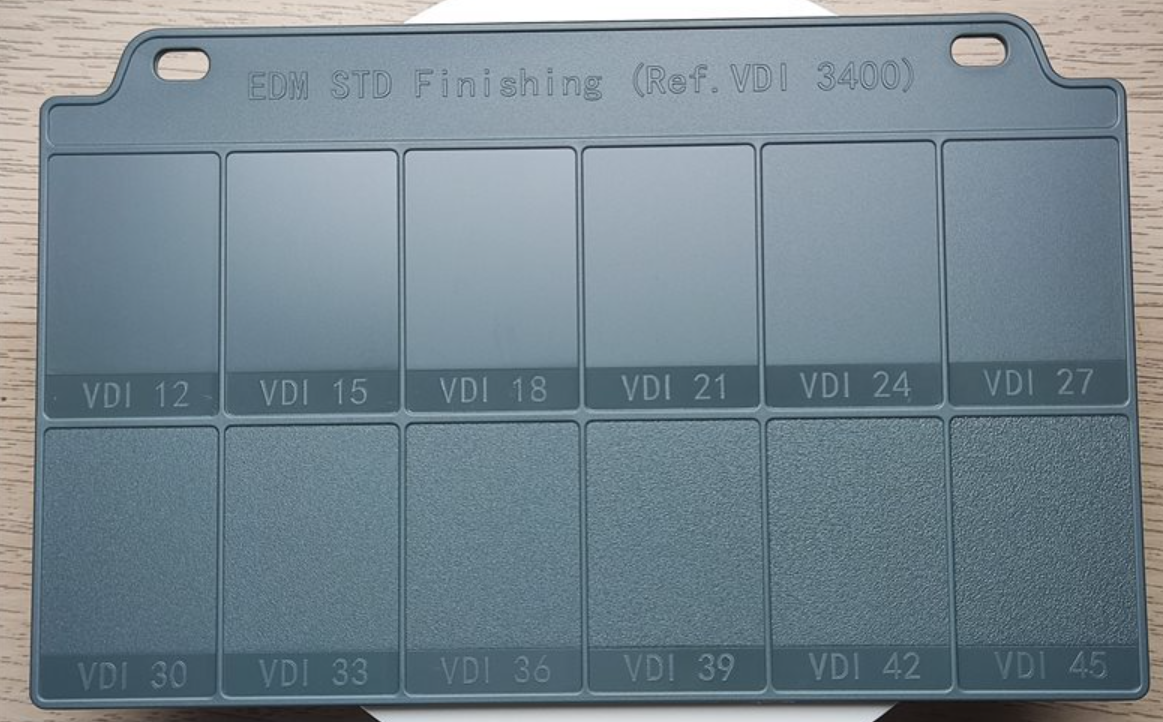

The VDI 3400 standard defines surface roughness levels from VDI 0 to VDI 45, with lower numbers indicating smoother finishes and higher numbers representing rougher finishes.

- VDI 0-15: Very smooth finishes, commonly used for optical components or high-gloss surfaces.

- VDI 18-30: Medium roughness, suitable for most consumer products.

- VDI 33-45: Rough finishes, often used for industrial parts where appearance is less critical.

Beyond functionality, mold surface texture also significantly impacts the aesthetic appeal of a product.

A smooth, polished surface can give a product a high-end, refined look. Additionally, appropriate roughness can enhance grip, improve the adhesion of coatings or overmolding materials, and enhance optical properties (especially for transparent components).

In optical applications, like lenses, the quality of polishing is paramount as it directly affects the performance of the optical device.

Mold surface texture technology is an essential aspect of product design. By carefully selecting the appropriate surface finish, manufacturers can enhance both the functionality and aesthetics of their products, ultimately improving their market competitiveness.